Overview of The Common Types of Gaskets

How Is Rubber Used In Your Daily Life?

February 27, 2019

Showcase Your Innovations at the IRC Expo

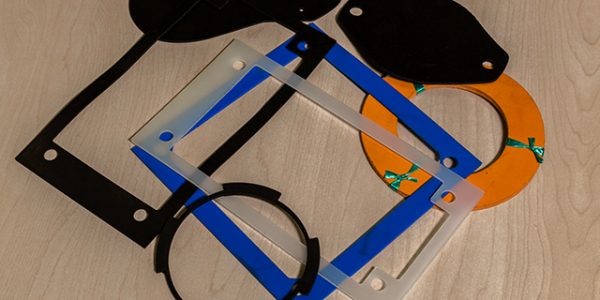

April 25, 2019Gaskets are used for various purposes in different industries. It is mainly made up of rubber, and it is used in types of machinery. There are different types of gaskets manufactured for specific applications. You would have come across rubber gaskets that were used in between two mechanical parts to prevent leakage in various machinery. The following are some of the common types of gaskets and the essential properties of gaskets.

Some of The Common Types of Gaskets and its Properties

Chloroprene Gasket

This type of gasket is made up of synthetic rubber. Chloroprene is the first type of synthetic rubber developed, and it is commercially called as Neoprene. This synthetic rubber possesses some unique properties like resistance to extreme climatic conditions. It is a versatile synthetic rubber which can be very well used in harsh environments and has resistance to petroleum and oil solvents.

Silicone Gasket

Silicone is one of the popular rubbers which are used for making gaskets. It is known for its high performance and its ability to withstand extreme temperatures. Thus this type of gasket is used in products that are subjected to high or low temperatures. This type of rubber is flexible even in the lower temperature of -75 degree Fahrenheit. Thus silicone gaskets are used for research in the Arctic region.

EPDM Gasket

Ethylene Propylene Diene Monomer is a popular type of rubber which is mostly used in various industries. It possesses specific versatile properties which makes it a preferred component for the manufacture of gaskets. This type of rubber is resistant to extreme temperature and gaskets made up of EPDM lasts for several years. It is ideal for use in outdoor equipment.

Properties Of Gaskets

The following are some of the features that a gasket should possess for the efficient functioning of machinery.

• The gasket that you use should be impermeable, i.e. it should not be porous.

• The gasket should be compressible, so it is possible to satisfy the intended purpose of the gasket.

• The gasket that you use should be creep and stress resistant so that it can withstand extreme load and temperature.

• Resilience is an essential property of a gasket that is required for its effective functioning.

• Gaskets should be chemical resistant so it can withstand damage caused due to chemicals. Thus the gasket material does not spoil the medium in which it is used.

• Gaskets should be able to withstand low and high temperatures.

• Gaskets must be anti-corrosive so that it does not cause corrosion.

The above knowledge on the types of gaskets would help to choose the right kind of gasket for your application.

Know More About : How Is Rubber Used In Your Daily Life?